Many advantages when working with SECU-CHEK UV-LED lamps

UV-LED Technology for Magnetic Particle Testing (MT, MPE, MPI), Penetrant Testing (PT), Fluorescent Penetrant Inspection (FPI), Ultrasonic Testing (UT) etc.

UV-LED Lamps in the industrial sector have to withstand many loads in a harsh environment in the daily work, especially when it comes to non-destructive testing (NDT).

SECU-CHEK UV-LED Lamps clearly stand out in the range of UV-LED lamp manufacturers based on years of experience and the highly technical and at the same time extremely practice-oriented approach of the SECU-CHEK team.

Get to know the advantages of the SECU-CHEK UV-LED lamps and let us advise you in order to be able to offer a solution that is optimally tailored to your individual test situation. We don’t shy away from any comparison – contact us for a free live demonstration at your location!

Pioneering Innovations for easy inspection

-

One hand inspection

-

White light function also usable without holding

-

the lamp follows the view of the inspector

-

wide range of accessories

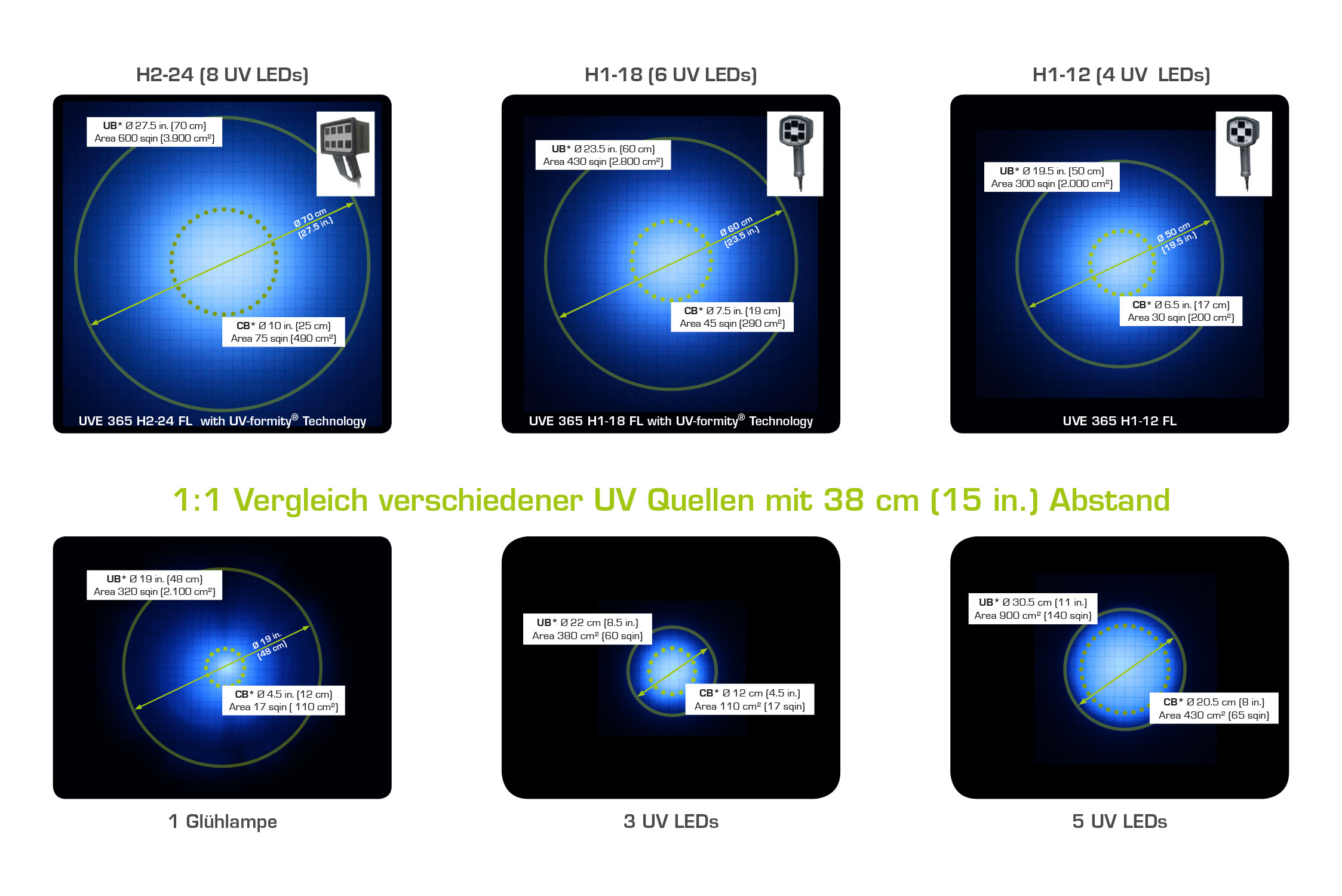

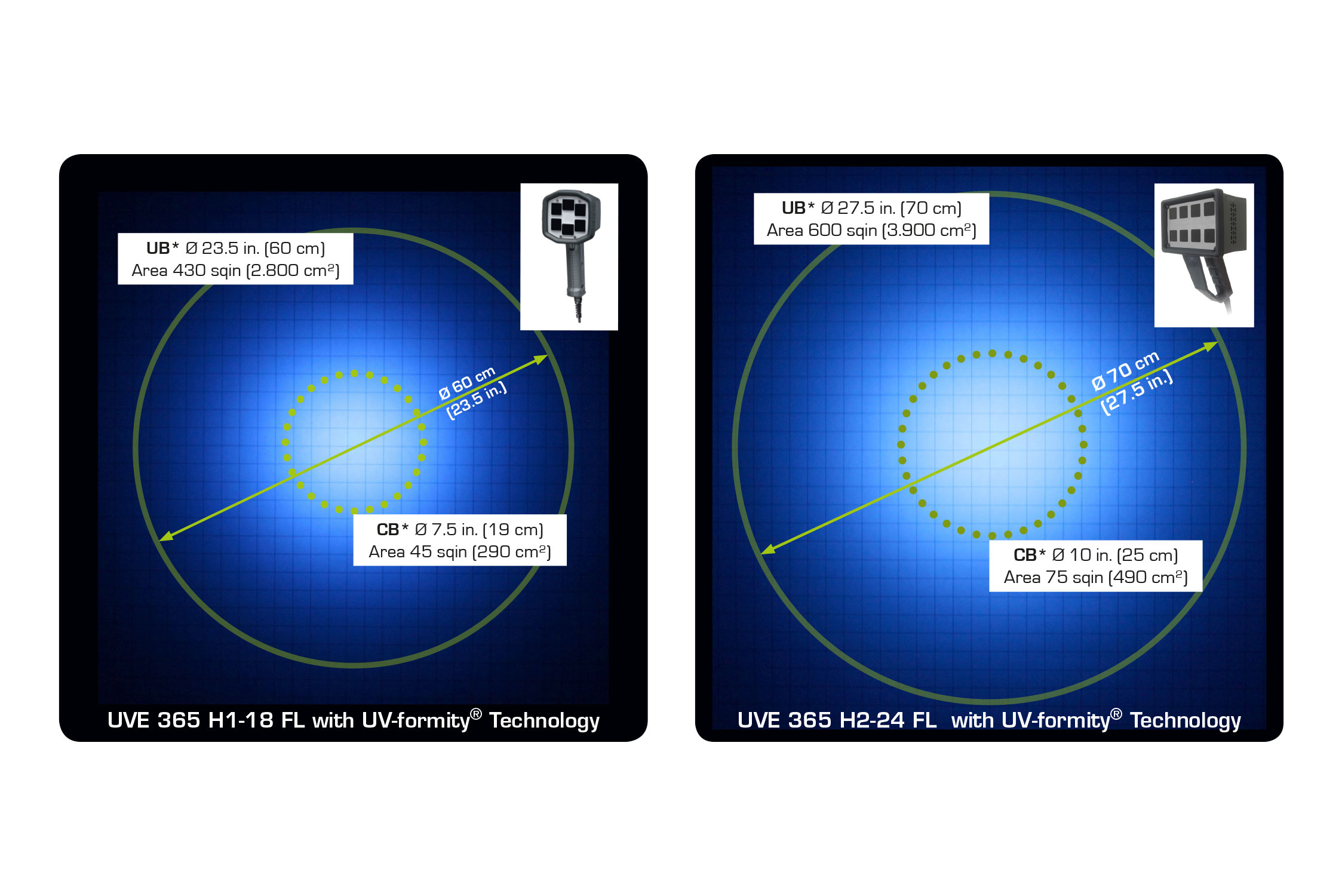

SECU-CHEK UV-LED lamps outperform standard UV-Lights

-

Larger usable and central beam

-

uniform and soft drop off to the edges

-

for optimized use of the human vision in dark areas

UV-formity ™ technology for optimized irradiation

-

The UV-formity ™ technology generates REAL and TOTAL UNIFORM irradiation in conjunction with large beams with soft drop from the centre to the edges even in short working distances.

UV-LED Handlamp Model overview and comparison

We at SECU-CHEK have therefore put together an overview and a UV-LED lamp comparison so that you can find out about the respective advantages and disadvantages of the corresponding UV-LED models.

Based on the applications such as Non-destructive material testing (NDT) or in the aviation industry there are certain requirements for the UV-LED lights. For example not every lamp is certified according to the standards of a particular engine manufacturer from the aviation industry.

The good news: with our H1 and H2 series in the field of UV LED handlamp models, all applications can be optimally covered.

We are happy to answer your questions and offer you an individual solution.

| Model overview |

|||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| typical areas of application: | ALL applications, preferably demanding long-term applications with increased requirements for process reliability in the aviation industry, in engine overhaul and in the automotive industry | fluorescent, non-destructive magnetic powder testing, penetration crack testing in continuous industrial use, cleanroom inspections | Leak detection, curing, drying, ZfP inspections, also in continuous use | ALL applications, preferably demanding long-term applications with increased requirements for process reliability in the aviation industry, in engine overhaul and in the automotive industry | |

| Variants: | H1-09 (3 UV-LEDs) | H1-09 (3 UV-LEDs) | H1-09 (3 UV-LEDs) | H2-24 (8 UV-LEDs) | 3 – 4 UV-LEDs |

| H1-12 (4 UV-LEDs) | H1-12 (4 UV-LEDs) | H1-12 (4 UV-LEDs) | |||

| H1-15 (5 UV-LEDs) | H1-15 (5 UV-LEDs) | H1-15 (5 UV-LEDs) | |||

| H1-18 (6 UV-LEDs) | H1-18 (6 UV-LEDs) | H1-18 (6 UV-LEDs) | |||

| Illumination: | Floodlamp or focused illumination |

Floodlamp or focused illumination |

Floodlamp or focused illumination |

Floodlamp or focused illumination |

Floodlamp or focused illumination |

| Optional white light functions: | automatic shiftable and dimmable white-light whose maximum brightness can be set during operation |

switchable white light that can be dimmed during operation | shiftable and pre-adjustable white light |

automatic shiftable and dimmable white-light whose maximum brightness can be set during operation |

No information |

| Specification and functions UV radiation | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Peak-Wavelength: | 365 nm (±5 nm) | 365 nm (±5 nm) | 365 nm (±5 nm) | 365 nm (±5 nm) | 365 nm (±5 nm) |

| Guaranteed peak wavelength during operation within the qualified ambient temperature | ● | ● | ● | ● | ● |

| Electronic Monitoring of the UV-LEDs | ● | – | – | ● | – |

| FWHM (Full Width Half Maximum): | ≤ 18 nm | ≤ 18 nm | ≤ 20 nm | ≤ 18 nm | |

| Constant operation of the LEDs (no pulses) | ● | ● | ● | ● | |

| Residual ripple of UV radiation: | ≤ 3 % | ≤ 3 % | ≤ 5 % | ≤ 3 % | |

| Number of UV LEDs: | 3, 4, 5 or 6* | 3, 4, 5 or 6* | 3, 4, 5 or 6* | 8 | 2 – 4 |

| Proportion of white light (measured at minimum working distance): |

≤ 5 Lux | ≤ 5 Lux | ≤ 16 Lux | ≤ 5 Lux | 5 Lux |

| Integrated UV-passfilter | ● | ● | optional | ● | No information |

| Typical lifespan T50: | ≥ 18.000 hours | ≥ 15.000 hours | ≥ 12.500 hours | ≥ 18.000 hours | 10.000 hours |

| Typical lifespan T70: | ≥ 15.000 hours | ≥ 12.500 hours | ≥ 10.000 hours | ≥ 15.000 hours | 5.000 hours |

| Features for advanced process and operational reliability | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Automatic shutdown and reactivation (eco-mode), switchable |

● | – | – | ● | No information |

| Safety switch off at low battery with time delay | ● | ● | ● | ● | No information |

| Safety switch off at low battery with prewarning | ● | – | – | ● | No information |

| Automatic adaption time signalization (1 minute) | ● | ● | ● | ● | No information |

| Adjustable adaption time signalization (1, 3 or 5 minutes) |

● | – | – | ● | No information |

| Custom lamp configuration by user | ● | – | – | ● | No information |

| Exchangeable rubber bumper with integrated protective sheave | ● | ● | ● | ● | No information |

| UV-intensity and illumination area | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| UV-A-Intensity in 15 inch (38cm) distance: | 1.500 – 15.000 µW/cm² * (15 – 150 W/m²)* |

1.500 – 15.000 µW/cm² * (15 – 150 W/m²)* |

1.200 – 12.000 µW/cm² * (12 – 120 W/m²)* |

1.500 – 15.000 µW/cm² * (15 – 150 W/m²)* |

~2.450 in 16 inch (40cm) distance |

| Irradiated area > 1.000 µW / cm² in 15 inch (38 cm): |

ø 13 up to 25 cm* | ø 13 up to 25 cm* | ø 10 up to 21 cm* | ø 13 up to 25 cm* | ø 20 cm |

| Irradiated area > 100 µW / cm² in 15inch (38 cm): |

ø 25 up to 52 cm* | ø 25 up to 52 cm* | ø 25 up to 52 cm* | ø 25 up to 52 cm* | ø 40 cm |

| Stability of UV-intensity: | ≥ 85 – 95 %* | ≥ 85 – 95 %* | ≥ 80 – 90 %* | ≥ 85 – 95 %* | No information |

| Risk class according to DGZfP EM6 (classification on occupational safety): |

2* (for Intensities > 80 W/m²: 3) |

2* (for Intensities > 80 W/m²: 3) |

2* (for Intensities > 80 W/m²: 3) |

2* (for Intensities > 80 W/m²: 3) |

2 |

| State signaling | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Blue signal-LED for UV-radiation | ● | ● | ● | ● | No information |

| No irritating yellow or green control-LEDs at UV-operation | ● | ● | ● | ● | No information |

| Multicolored control-LED | ● | ● | ● | ● | No information |

| Separate control-LED for UV and white light | ● | ● | – | ● | No information |

| Acoustic signal | ● | ● | ● | ● | No information |

| Tactile vibration signal | ● | – | – | ● | No information |

| Fast, safe and easy status display in the user’s view | ● | ● | ● | ● | No information |

| Possible qualifications, approvals and fulfilling requirements | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Guaranteed requalification possibility for upcoming DIN, EN, ISO and ASTM standards | ● | ● | – | ● | No information |

| Qualified ambient temperature range | 5 – 50° C | 5 – 50° C | 5 – 40° C | 5 – 50° C | 10 – 35° C |

| Detailed certificate and test report | ● | ● | – | ● | No information |

| DIN EN ISO 3059: 2013-3 (Conditions of observation) | ● | ● | ● | ● | No information |

| DIN EN ISO 9934: 2013-05 (Magnetic powder test) | ● | ● | ● | ● | No information |

| DIN EN ISO 3452: 2014 (Penetration test) | ● | ● | ● | ● | No information |

| ASTM E-2297-04 (2010) (Guide for magnetic powder testing and penetration testing) | ● | ● | ● | ● | No information |

| ASTM E-3022 (UV-LED-lamps) | ●* | ●* | ●* | ●* | No information |

| ASTM E-1444 M-12 (Magnetic powder test) | ● | ● | ● | ● | No information |

| ASTM E-1417 M-13 (Penetration test) | ● | ● | ● | ● | No information |

| Rolls-Royce RRES 90061 (Qualification of UV LED lights) |

●* | ●* | ●* | ●* | • (1 of 4 devices) |

| MTU Aero Engines | ● | ● | ● | ● | No information |

| Safran Groupe (SNECMA, Turbomeca) | no requirement available | no requirement available | no requirement available | no requirement available | no requirement available |

| Airbus AITM6-1001 (Penetration test) | ● | ● | ● | ● | No information |

| Pratt & Whittney SPM (PN 585005) (Penetration test) | ● | ● | ● | ● | No information |

| ASME-Code (BPVS) (Magnetic powder and penetrant testing) | ● | ● | ● | ● | No information |

| NADCAP (Aviation auditing) | no requirement available | no requirement available | no requirement available | no requirement available | no requirement available |

| Boeing | no requirement available | no requirement available | no requirement available | no requirement available | no requirement available |

| General Electric Aviation (GE) | no requirement available | no requirement available | no requirement available | no requirement available | no requirement available |

| Controls, external control and integration in plants | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Integrated touch switch | 1 / 5* | 1 / 5* | 1 / 2* | – | |

| Comfortable one-hand operation of the white light functions | ● | ● | ● | ● | – |

| HOLD function for fixing the white light condition | ● | ● | – | ● | – |

| Connection possibility for external control of the white light, e.g. by foot switch | ● | – | – | ● | – |

| Connection for external foot dimmer | ● | – | – | ● | – |

| Control of the luminaire via external machine control (for example PLC of the test bench) | ● | – | – | ● | – |

| Feedback of the operating state to external control, triggering of external alarms in case of fault or logging by PLC | ● | – | – | ● | – |

| Direct switching on of the luminaire can be adjusted with voltage supply | ● | – | – | ● | – |

| Integrated appliances for standard fixtures | ● | ● | ● | ● | – |

| Functions and specifications of optional, integrated white light | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Preset white light brightness | ● | ● | ● | ● | |

| White light brightness can be changed during operation | ● | ● | – | ● | – |

| Changeover Between UV radiation and white light |

● | ● | ● | ● | • (1 of 4 devices) |

| Integration of white light with UV radiation | ● | ● | – | ● | – |

| Automatic adjustment of white light to UV radiation |

● | – | – | ● | – |

| Automatic cross-fading Between UV radiation and white light |

● | – | – | ● | – |

| Variety of white light with relapse option during operation | ● | – | – | ● | – |

| Uniform, flat, blinding illumination | ● | ● | ● | ● | – |

| Illuminance (Lux) In 38cm distance: |

up to 5.000 lux* | up to 5.000 lux* | up to 1.500 lux* | up to 5.000 lux* | |

| Color temperature: | 5.300 K – 6.500 K | 5.300 K – 6.500 K | 5.300 K – 6.500 K | 5.300 K – 6.500 K | |

| Color rendering index (Ra): | ≥ 90 | ≥ 90 | ≥ 70 | ≥ 90 | |

| Electrical specifications | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Type of power supply: | External power supply (AC / DC) or External rechargeable battery (LiIon or NiMH) |

External power supply (AC / DC) or External rechargeable battery (LiIon or NiMH) |

External power supply (AC / DC) or External rechargeable battery (LiIon or NiMH) |

External power supply (AC / DC) or External rechargeable battery (LiIon or NiMH) |

|

| Power consumption: | 15 W – 50 W* | 15 W – 50 W* | 15 W – 25 W* | 15 W – 50 W* | |

| max. Operating voltage Handset: | 50 V DC | 50 V DC | 50 V DC | 50 V DC | |

| Protective low voltage on handset: (≤ 60 VDC) | yes | yes | yes | yes | |

| Protection class: | IP 20 with protected electronics | IP 20 with protected electronics | IP 20 with protected electronics | IP 20 with protected electronics | |

| Protection class: | III (Protective low voltage) | III (Protective low voltage) | III (Protective low voltage) | III (Protective low voltage) | |

| Technical specifications | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Dimensions: | 160 x 105 x 95 mm ( 6,3 x 4,1 x 3,7 inch) |

160 x 105 x 95 mm ( 6,3 x 4,1 x 3,7 inch) |

160 x 105 x 95 mm ( 6,3 x 4,1 x 3,7 inch) |

||

| Weight of lamp head: | 0,70 kg – 0,85 kg* | 0,70 kg – 0,85 kg* | 0,70 kg – 0,85 kg* | ||

| Active air cooling for maximum service life and safe operation | ● | ● | ● | ● | |

| Electronic monitoring of the fan | ● | ● | ● | ● | No information |

| Safety shutdown at overtemperature | ● | ● | ● | ● | No information |

| Extra quiet, temperature controlled fan controller | ● | – | – | ● | No information |

| Operating conditions | |||||

| Series: | UVE 365 H1 | UVN 365 H1 | UVS 365 H1 | UVE H224 | Competition |

| Humidity in %: | 20- 80 % (not condensing) | 20- 80 % (not condensing) | 20- 80 % (not condensing) | 20- 80 % (not condensing) | No information |

| Permissible ambient temperature: | 5 – 50° C | 5 – 50° C | 5 -40° C | 5 – 50° C | 10 – 35° C |

We reserve the right at any time to make technical modifications without announcement.

*: depend on model

NDT-Journal edition 153 technical article: 16 SECU-CHEK UV LED lights meet the manufacturer standard Airbus AITM 6-1001 (Issue 11)

In order to guarantee test results that are as reliable as possible, the processes and tools of the employees, suppliers, suppliers, etc. must meet certain NDT standards. The DGZfP and various other organizations and some of the manufacturers themselves publish these standards. This gives companies the opportunity to meet the critical criteria in the area of UV LED technology with the appropriate UV lamps.

SECU-CHEK as a highly specialized manufacturer of UV LED lights is a member of DGZfP e.V. and was mentioned in the NDT newspaper with a technical contribution when the new manufacturer standard Airbus AITM 6-1001 (Issue 11) was published.

You can download the entire NDT journal edition 153 including this technical article as a PDF from the international platform NDT.net:

Publication 2017-02: e-Journal of Nondestructive Testing (NDT) ISSN 1435-4934 (NDT.net Journal)

Read the contribution from the NDT newspaper on NDT and Airbus AITM 6-1001 (Issue 11) here:

The UVE series was developed under the aviation slogan: “FAILURE IS NOT AN OPTION”, which should always apply to NDT, for uncompromising, reliable and safe testing.

The floodlights of the UVE series are characterized by extremely uniform illumination, even at short working distances, as well as a very gentle radiation drop at the edge. In contrast to commercially available UV LED lights, the illumination area is much more uniform with a larger central evaluation area.

The advantages of the mercury vapor lamp and LED technology have been combined so that these lamps can be tested better, faster and just as safely as with discharge lamp-based UV lamps Test costs can be significantly reduced.

The microprocessor control, with more than 15,000 lines of software code, provides extended functions, such as the adjustable adaptation time signaling, and monitors the luminaire fully electronically. For example, the UV radiation is automatically switched off in the event of the failure of a single UV LED element or insufficient battery power.

Eight of the 16 models are equipped with the groundbreaking automatic dimming. The continuous dimming of the white light and the cross-fading between UV radiation and white light, at the push of a button, to the adjustable brightness enable an optimized evaluation without flashing the eyes.

The resulting continuous viewing of the fluorescent displays, even when using the white light, allows a safer, faster and fatigue-free evaluation and assessment without stressing the eyes.

In order to experience the high performance and robustness of the lights in practice, SECU-CHEK offers demonstrations on site as well as free one-week test orders.

If you are interested, contact SECU-CHEK at +49 (0)6805-942859-0 or click on www.secu-chek.com

Source/PDF: NDT Journal issue 153 (2017-02)

Further standards and qualifications are: ASTM E-3022, EN ISO 3059, Airbus AITM 6-1001 Issue 11, Airbus AITM 6-1001 Issue 12, Boeing, NADCAP AC 7114/1 and 7114/2, Pratt & Whitney FPM, Rolls Royce RRES 90061, United States Airforce (USAF). In addition to the standards listed here, we offer many further qualifications – ask us, we are happy to help!

SECU-CHEK offers you a wide range of UV-LED Lamps perfectly adapted UV-LED equipment for your individual test situation - and that with personal project support from A to Z by our NDT experts

We look forward to your inquiry!

You are also welcome to contact us by phone or email.

Direct contact:

SECU-CHEK GmbH

An der Fähre 9

66271 Kleinblittersdorf

GERMANY

Phone +49 6805-942859-0

Fax +49 6805-942859-95

Email: info@secu-chek.de